It has been incorporated into state regulations, such as those adopted in Tasmania, Western Australia, and in Queensland under the Radiation Safety Act 1999. In Australia, the AS/NZ 2211(Laser Safety), and the 4173, (Guide to the Safe Use of Lasers in Healthcare), have become the expected standard for laser safety in healthcare, and though not regulatory, have taken on the impact of regulation through its wide acceptance. This serves as a strong motivation for laser users to gain knowledge of the established rules for safety, and mandate compliance with them.

As such, they are often considered as the usual and customary practice in a given area, and are the basis for medical-legal decisions in cases of patient or staff injury, accident, or untoward occurrence. Standards are non-regulatory, but serve as consensus documents for best practice.

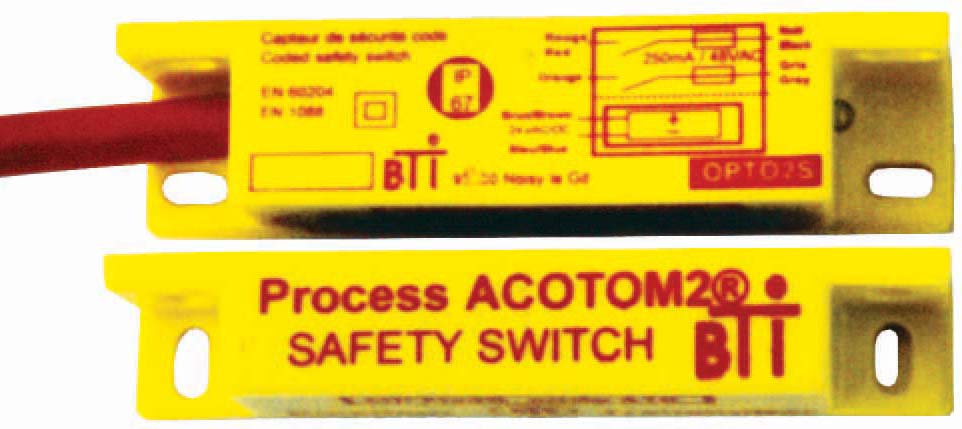

#BTI SAFETY SWITCH MAX 4 PROFESSIONAL#

In some countries (USA, Australia, Canada), these standards are harmonized with the national standards, and are mandated as the basis for all additional regulations and professional recommended practices. They are used as the foundation for most country's national standards. These standards are the global benchmarks for laser safety, and include normative and informative guidance for manufacturers, professional clinicians, and administrators of laser use facilities. International standards are available through the International Electrotechnical Commission (IEC), documents 60601, 60825, and 60825-Part 8. Risk Management Step One: Knowledge of Standards, Regulations, and Practice Guidelines Proper safety management requires a fourfold approach including: knowledge of standards, identification of hazards and risks, implementation of appropriate control measures, and consistent program audit to demonstrate quality assurance. Of all hazards, complacency is the most dangerous, and it is imperative to develop a risk management perspective on laser safety. Laser safety is EVERYONE'S concern! A laser is as safe or as hazardous as the user–and that user's knowledge and skill, defines how well laser safety is managed. This should be the goal of all who are involved with the sale, purchase, application, and management of all medical laser systems–under all circumstances. What remains, regardless of the practice site, application, or system in use, is the constant goal of establishing and maintaining a laser safe environment for the patient, the staff, and the user, at all times.

#BTI SAFETY SWITCH MAX 4 ISO#

to EN ISO 13849-1 : 1 switch up to PLd cat.Now that laser technology has emerged from hospital operating rooms, and has become available to office practices, clinics, and private enterprises, the burden of responsibility for safety has shifted from hospital staff to the individual user, often without benefit of appropriate or adequate resources. Mechanical life expectancy : 50.000.000 operationsĮlectromagnetic immunity : Acc. Safety outputs: 2 NO outputs 48V AC, 30V DC, 2AĮlectronic double coding with self-control : ACOTOM®

This safety product must be checked at least once a year.

The receiver supplies two potential-free NO safety lines and an NC PNP (AMX5 or AMX5OX) auxiliary contact.

A sensor consists of two PA6 or 316L stainless steel (AMX5OX) transmitting and receiving parts. It is able to detect its own failure and lock itself, preventing the safety line from closing. AMX4 and AMX5 devices are coded electronic autonomous sensors using our ACOTOM3® process, allowing the opening of mobile protectors on dangerous machines to be detected.

0 kommentar(er)

0 kommentar(er)